-40%

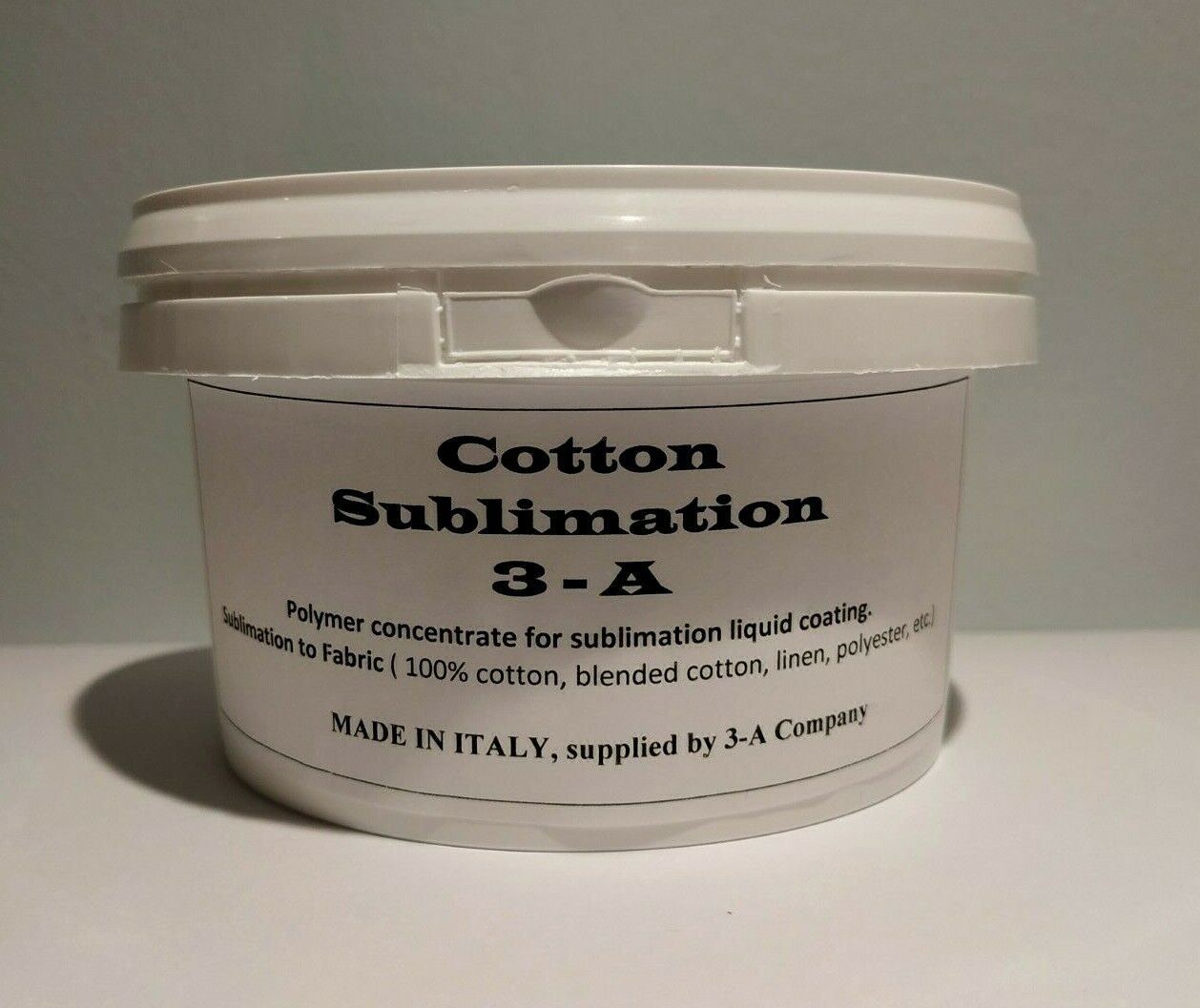

Sublimation spray/coating for 100% cotton. 68 oz (2 litres). 3-A brand

$ 13.19

- Description

- Size Guide

Description

Cotton Sublimation polymer coating.Made in Italy

. Very high quality and easy to use.

3 - A Brand

.

Polyamide polymer concentrate for sublimation liquid coating.

Sublimation to Fabric ( 100% cotton, blended cotton, linen, polyester, etc.)

The concentrate is paste form, shelf life 1 year ( 10 months after your ordering), stored in place away from sunlight, in temperature 5-40 grade celsius.

Note: We offer concentrate to make coating liquid for cotton.

The packaging contains

400gr ( 0.4 kg) polymer concentrate 3-A brand.

With 0.4 kg

3-A brand polymer concentrate

you can make 2 litres (4.4 lbs) liquid coating

[ 0.4kg concentrate + 1.6kg water =

2 litres (4.4 lbs) liquid coating

]

Video Tutorial:

1. How to make Liquid coating 3-A brand:

https://www.youtube.com/watch?v=FBbMLSvD6rE

2. How to make sublimation to 100% cotton with 3-A polymer coating :

https://www.youtube.com/watch?v=397PZVfBrUQ

TRANSFER CONDITIONS

MATERIAL

TEMPERATURE

TIME

Cotton

180°C (or higher)

50-60 sec

The paper may be printed with every kind of sublimation ink.

Such paper has to be transferred at a minimum temperature of 180°C or higher (depending of the ink), for a time of 50/60 seconds, quality of the fabric permitting.

It is essential that the peeling of the paper takes place immediately after hot transferring (hot split), in order to avoid that the paper peels off not perfectly

Instructions

1.

Make the liquid coating

(mix polymer concentrate with water at

Rate 1:4

,

1

concentrate : 4 natural water

)

2.

Spray well the fabric with polymer liquid coating.

3.

Cure well the fabric before to press in heat press.

4.

Press for sublimation with medium pressure for 50-60 seconds at 180

0

C

or higher ( depending of the ink)

Heat cures

: heat gun ( hair dryer ) , tunnel dryer etc.

Note:

Mix well the concentrate with water for more than 3 minutes, for good homogenization (you can mix with kitchenware mixer, electric hand-mixer).

SPECIAL INSTRUCTIONS

·

Always test the application characteristics, before starting production.

·

It is recommended to do preliminary tests, in order to determine the right transfer time and temperature

.

GENERAL FEATURES

·

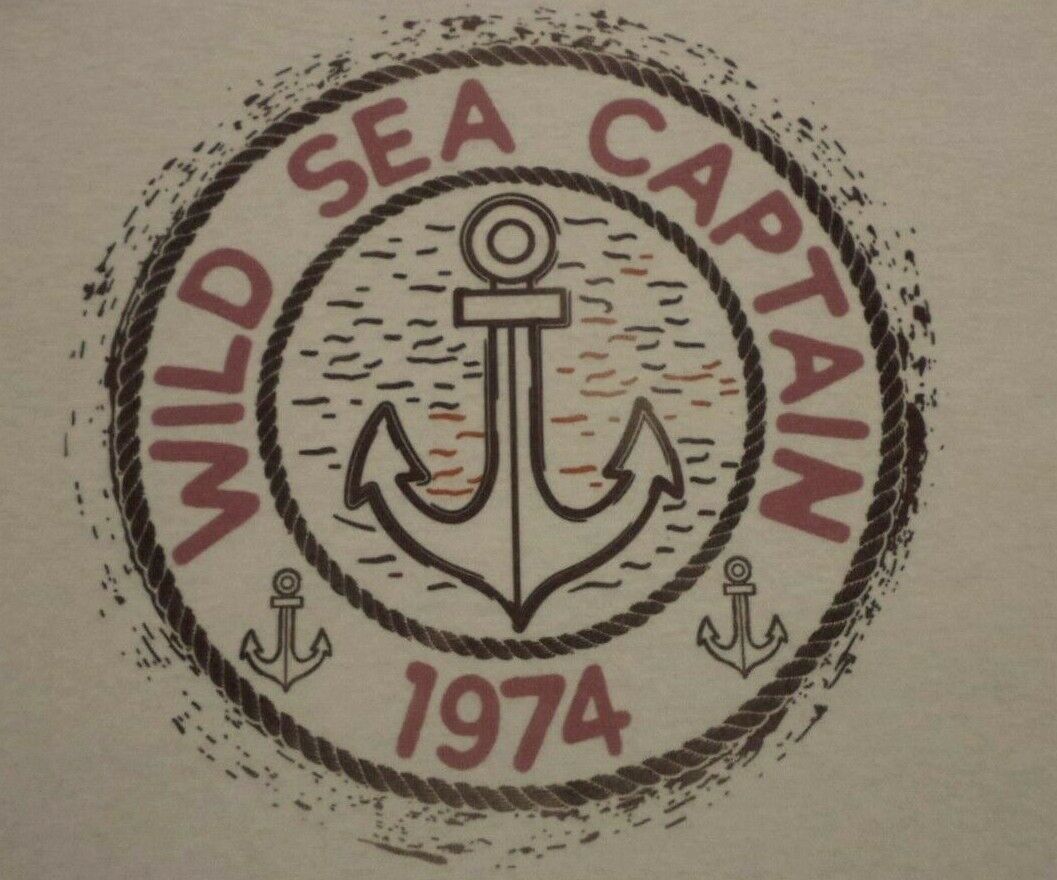

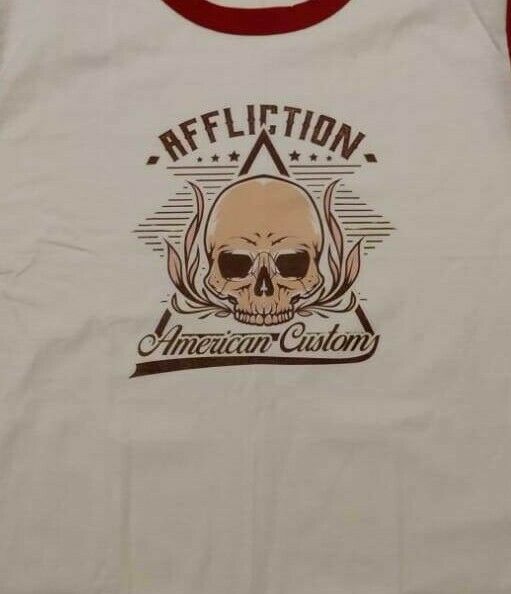

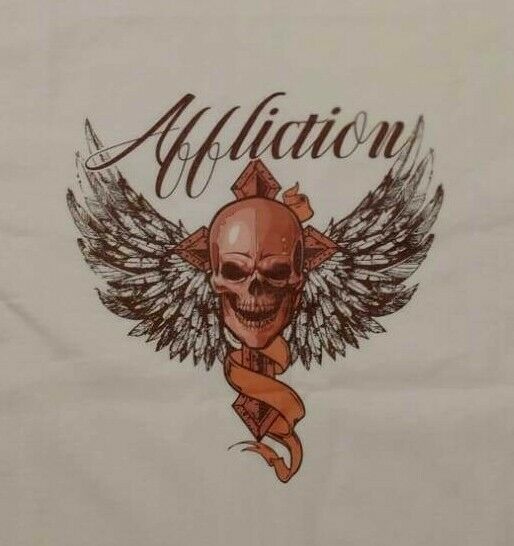

Good color performance after sublimation

·

Soft touch

·

Good washing resistance (40°C)

·

Free from risk labelling

Always test samples prior to production runs.

NON – FLAMABLE., IRRITATING TO EYES & RESPIRATORY SYSTEM, DO NOT SWALLOW.